IPS e.max System

IPS e.max System

We absolutely love to work with this system simply because there's no limit on the Aesthetic results you can achieve. We believe if you ain't using E.max your most definately missing out.

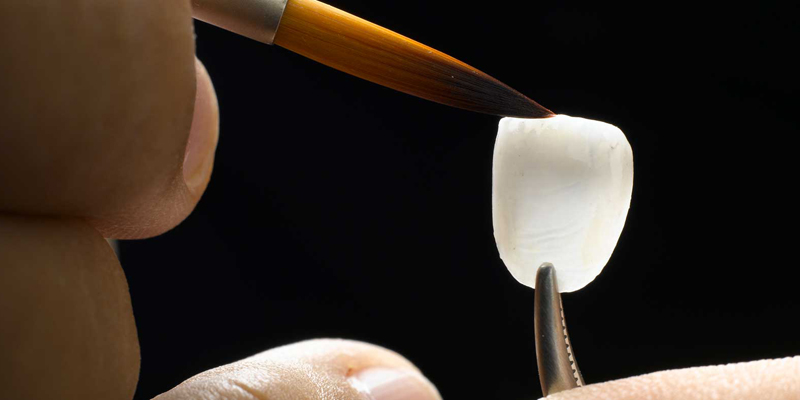

Designed with simplicity and versatility in mind, IPS e.max is the ultimate in metal-free esthetics and durability offering high-strength materials for both the PRESS and the CAD/CAM technique.

No matter which technique you choose, all components are available from one manufacturer. If you prefer to work with the PRESS technique, two different types of ingots are available: IPS e.max Press, a high-strength glass-ceramic and IPS e.max ZirPress, an esthetic glass-ceramic which is pressed onto zirconium oxide in a fast and efficient procedure. For CAD/CAM applications, either the highly esthetic IPS e.max CAD ceramic glass blocks or the high-strength IPS e.max ZirCADzirconium oxide can be selected, depending on the case requirements. The nano-fluorapatite layering ceramic IPS e.max Ceram completes the all-ceramic system. This material is used to veneer all IPS e.max components, no matter if they are glass-ceramic or zirconium oxide

The IPS e.max all-ceramic system covers the entire spectrum of indications ranging from thin veneers to 10-unit bridges. The IPS e.max restorations are highly esthetic and exhibit outstanding mechanical strength.

Depending on the indication and the required strength, dentists can choose the most suitable all-ceramic material. Lithium disilicate (LS2), which demonstrates superb esthetic properties, is used to restore single teeth in the anterior and posterior region. The zirconium oxide ceramic IPS e.max ZirCAD, however, is the material of choice for large restorations, for example posterior bridges, which are exposed to high masticatory forces.

E.MAX PRESS CERAMIC BENEFITS

• Cementable: Pressing eliminates porcelain porosity resulting in higher strength.

• Precise Fit: No Condensation Shrinkage improves fit and reduces adjustment time.

INDICATIONS

Anterior Crowns: Optimal esthetics and reliable strength are achieved by “pressing” the e.max lithium disilicate into a coping, then veneering the coping with Ivoclar’s e.max Ceram to achieve translucency and internal effects.

Posterior Crowns: The e.max posterior crown is pressed to full contour, then stained and glazed. This “Monolithic “ crown has the high strength you need for posterior cementation.

WHY A MONOLITHIC CROWN

The weak link in any PFM crown, or any zirconia crown, is not the coping. Cast metal or milled zirconia copings are both strong enough (>1000mpa). But the interface between the coping (25-40mpa) and the porcelain veneer (90-110mpa) built to cover the coping, are inherently weaker. Most observers agree, ceramic failures, whether on metal or zirconia, fail at these two “weak” points.

An e.max pressed “Monolithic” crown has no interface, and no layered veneer. And because the ceramic ingots are blended with dentin colored and translucent ceramics, these posterior crowns match posterior dentition with slight translucency in cusp tips.